Product Description

| Product name | 10Ml Roller Glass Bottle Bamboo Roller Perfume Bottle |

| Usage | Glass Bottle for Cosmetics,Essential Oil |

| Capacity and size | 5ml 10ml |

| Technics | Ingredients:Sand—70%, Soda Ash—15%, Limestone—10% |

| Material : ordinary white glass , high white glass, Ultra-white glass, White Crystalline glass, They are all Eco-friendly, Good Health is the Best! | |

| Sample | Free Sample,first cooperation freight charge will be paid by customer, The Charge will be Refundable when you place an order. |

| Logo printing | Jar logo and carton logo will be customized by client request, Weclcome Customized,Let Your Logo Unique ! |

| Deep precessing of surface | Frosted, Decal , Color spray, Screen printing , engave, Lable ,electoplating Put Your Good Idea into Reality ! |

| MOQ | 1000pcs if we have stocks,For unique designed bottles, we can discuss accordingly. More Quantity Much Cheaper! |

| Qualiy Guarantee | We have 1:1 replacement for defective bottle Carefully |

| Safety Guarantee | We can make 1:1 compensate for the broken bottle for free |

| Package | pallet + carton board +shrink film |

| pallet+carton + dividers | |

| other pakaging methods as per your need and requirement. Accept Your Special Demands, Let You Save Time and Worries! | |

| Delivery time&way | 20-30 days after receiving deposit |

| By sea /air to your nearest airport | |

| By express (DHL,UPS,FEDEX,TNT,EMS)to your door | |

| We are High-Level Contracted Partner of DHL, Fedex, UPS , and other International Express Company.We also have Long Cooperative with MAERSK, COSCO, CSCL and other International Ship company. Make the Goods Quickly, Efficiently and Low Cost to Reach Your Hands. | |

| Other Services | When You Become Our VIP, We will send Our Lastest Samples Freely Along with Your Every Shipment. You can Enjoy Our Distributor Price and All Your Orders will Have the First Priority to Arrange Production and etc. |

FAQ

1,How can we know these are really lead free and food grade?

As usual for glass we have common material , high white material, crystal white material, all these material are suitable for food grade and lead free, we pass SGS, food grade test,no need to worry safety.

2, How can I get a sample to check your quality? Do you offer free sample?

— Yes, free samples are available,direct trade assurance order is allowed. Only freight cost is on your side which will be refundable once the order was placed. Or if you have a courier account, we can arrange samples by collected.

3,How about the Safe package and defective and broken questions?

— For small order or samples, we all use bubble bags or foam to pack 1 by one, so far customers who placed small orders have not yet feedback about the damaged problem.

–For large quantity of container order, we support the standard export pallet package or paper carton with safe egg packing. Also we accept customized gift box.

–Other accessories like caps will put in another carton to avoid hitting. We will guarantee the broken rate under 0.2%.

–We will compensate the defective and broken bottles by your next order freely.

4,What surface handing could you support? Shall we do our logo on it?

–Sure, we can do the logo as you need and support decoration firing ,screen printing, hot stamping, frost, label printing etc.

–About printing color: it can be made according to PANTONE color number.

5, How about the sealing?

For glass jar, we have glass lids, plastic caps, metal caps and ect ,all these kinds of lids will be matched with the jar perfectly and sealing very well. There is a small strip of rubber under the lid where the glass hits the lid. They seal pretty well.Food-grade rubber in line with EU export standards,the lids are very easy to screw on and off. Just 1 twist for on and 1 for off.

6,What about the lead time?

— samples will be send within 12-24hours after we receive your payment;

–small orders will be delivery within 7-10 days after we receive your payment.

–large quantity orders will be delivery with 20-25days.

7,What is your payment?

–For sample or trial order,we accept Paypal,western union and trade assurance.

–For larger orders,T/T or L/C or trade assurance will be acceptable.

8,What’s your shipping terms?

For samples or trial order,FEDEX,DHL,UPS ,TNT,ARAMEX can be provided.

For larger orders,delivery by air or sea or rail accord to your requirements, we will try to help you to choose the best way depending your actual situation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Glass |

|---|---|

| Usage: | Cosmetics |

| Sealing Type: | Screw Cap |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample sample is free, you only need pay delivery cost

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

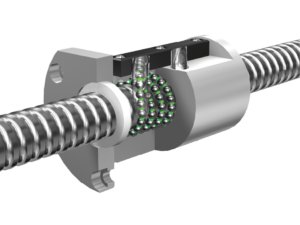

How do you determine when a screw ball needs to be replaced?

Determining when a screw ball, also known as a ball screw, needs to be replaced requires careful assessment of its condition and performance. Several factors should be considered to determine if replacement is necessary. Here are some key indicators to help determine when a screw ball needs to be replaced:

- Excessive Wear: If the screw ball has undergone significant wear, such as worn ball bearings, damaged raceway, or excessive backlash, it may be an indication that replacement is necessary. Visual inspection and measurements of critical dimensions can help assess the extent of wear and determine if it has reached a point where replacement is warranted.

- Reduced Performance: A noticeable decline in the performance of the screw ball assembly, such as decreased positioning accuracy, repeatability, or load-carrying capacity, can indicate the need for replacement. If the system is no longer meeting the required specifications or is unable to perform its intended function reliably, replacement should be considered.

- Severe Damage: If the screw ball has suffered severe damage, such as fractures, deformations, or extensive pitting and corrosion, it is likely beyond repair and should be replaced. Severe damage can compromise the structural integrity and functionality of the assembly, leading to safety risks and unreliable operation.

- Frequent Failures: If the screw ball assembly is experiencing frequent failures or breakdowns, even after repairs or maintenance efforts, it may indicate that the wear and tear have reached a critical point. Frequent failures can result in costly downtime, reduced productivity, and increased maintenance costs. In such cases, replacing the screw ball assembly can be a more cost-effective solution in the long run.

- Unrepairable Issues: Certain issues with the screw ball assembly may be unrepairable or uneconomical to fix. For example, if the assembly has been subjected to severe contamination or exposure to corrosive substances that have caused irreversible damage, replacement may be the only viable option. Similarly, if critical components or specialized parts are no longer available or obsolete, replacement may be necessary.

- Manufacturer’s Recommendations: It is important to consult the manufacturer’s recommendations and guidelines regarding the expected lifespan and replacement intervals for the specific screw ball product. Manufacturers often provide guidelines on the maximum allowable wear, recommended maintenance practices, and replacement criteria. Adhering to these recommendations can help ensure safe and reliable operation.

It is crucial to thoroughly assess the condition of the screw ball assembly and consider the impact of its performance on the overall system. Regular inspection, maintenance, and monitoring can help identify signs of wear, damage, or decline in performance. If any of the above indicators are present, consulting with experts or the manufacturer can provide valuable insights and guidance on whether replacement is necessary.

When replacing a screw ball, it is important to select a suitable replacement that meets the application requirements, including load capacity, accuracy, speed, and environmental considerations. Proper installation, lubrication, and maintenance of the new screw ball assembly are also essential to ensure optimal performance and longevity.

Are there specific environmental conditions where screw balls perform best?

Screw balls, also known as ball screws, are versatile linear motion systems that can perform well in a wide range of environmental conditions. However, there are specific conditions where screw balls are particularly well-suited and can deliver optimal performance. Here are some environmental conditions where screw balls perform best:

- Clean and Dry Environments: Screw balls are highly effective in clean and dry environments. They are designed to operate with minimal friction, and the rolling contact between the ball bearings and the raceway helps reduce wear and extend the service life of the system. In clean and dry environments, there is less likelihood of contaminants or moisture affecting the performance of the screw ball assembly.

- Controlled Temperature: Screw balls are typically designed to operate within a specific temperature range. Extreme temperature variations can affect the performance and dimensional stability of the components. Therefore, screw balls generally perform best in environments with controlled temperature conditions, where the temperature remains within the specified operating range.

- Low to Moderate Vibration: Screw balls can tolerate low to moderate levels of vibration. However, excessive vibration can impact the accuracy and smoothness of the linear motion. Therefore, environments with low to moderate vibration levels are more suitable for screw ball applications. In cases where high vibration is present, additional measures such as vibration isolation or dampening techniques may be required.

- Low to Moderate Dust or Particle Exposure: Screw balls can operate effectively in environments with low to moderate levels of dust or particle exposure. However, excessive dust or particle contamination can hinder the smooth rolling motion and cause wear or damage to the ball bearings and raceway. In such cases, protective measures such as seals or covers can be employed to shield the screw ball assembly from contaminants.

- Moderate Humidity: Screw balls can tolerate moderate humidity levels. However, high humidity environments can lead to corrosion or moisture ingress, affecting the performance and longevity of the system. In humid conditions, appropriate sealing and corrosion-resistant materials should be considered to maintain optimal performance.

- Absence of Chemical Exposure: Screw balls are not suitable for environments where they come into direct contact with corrosive chemicals or aggressive substances. Chemical exposure can damage the ball bearings, raceway, and lubrication, leading to premature failure. It is important to ensure that screw balls are protected from chemical exposure or choose alternative materials that can withstand such environments.

While screw balls can perform well in various environmental conditions, it is crucial to consider the specific requirements and limitations of the application. Understanding the environmental factors and potential challenges can help in selecting appropriate screw ball configurations, materials, and protective measures to ensure optimal performance and longevity.

How do you select the right size of a screw ball for a specific application?

Selecting the right size of a screw ball, or screw, for a specific application involves considering several factors that influence the functionality and performance of the screw. Here are some key considerations when determining the appropriate size:

- Thread Type: The first step in selecting the right screw size is to determine the thread type required for the application. Common thread types include machine screw threads, wood screw threads, self-tapping screw threads, and sheet metal screw threads. Each thread type has specific dimensions and characteristics that influence the choice of screw size.

- Diameter: The diameter of the screw is a critical factor in determining its size. It is typically measured as the major diameter, which is the outside diameter of the threaded portion of the screw. The diameter should match the size of the hole or the material being fastened. Using a screw with the correct diameter ensures proper thread engagement and adequate holding strength.

- Length: The length of the screw is determined by the thickness of the materials being joined. The screw should be long enough to penetrate through the first material and provide sufficient engagement in the second material to create a secure connection. It is important to consider the total thickness of the materials and any additional components, such as washers or spacers, when determining the appropriate screw length.

- Head Type: The head type of the screw should also be considered for specific applications. Common head types include flat head, pan head, round head, and countersunk head. The choice of head type depends on aesthetic preferences, flushness requirements, and the type of tool used for installation.

- Material: The material of the screw should be selected based on the application’s environmental conditions and the materials being fastened. Different materials offer varying levels of corrosion resistance, strength, and compatibility with specific materials. Common screw materials include stainless steel, carbon steel, brass, and aluminum.

- Load and Application: Consider the anticipated load and the specific application requirements. If the screw will be subjected to heavy loads or vibrations, it may be necessary to choose a larger size or a screw with additional features like locking threads or increased tensile strength.

When selecting the right size of a screw ball, it is essential to consult the manufacturer’s specifications, guidelines, or engineering resources specific to the application. These resources often provide detailed information on recommended screw sizes based on the intended use, material compatibility, and load requirements.

It is also advisable to consult with professionals, such as engineers or experienced tradespeople, who have expertise in the specific application or industry. They can provide valuable insights and recommendations based on their experience and knowledge of best practices.

By considering factors such as thread type, diameter, length, head type, material, load, and application requirements, the appropriate size of a screw ball can be selected to ensure optimal performance, durability, and reliability in a specific application.

editor by CX 2024-03-06

Leave a Reply