Product Description

1.Can you provide sample free?

Yes ,we can provide free samples with in 0.5kg.

2.What kind of payment terms you can accept?

We can accept T/T,L/C, Western Union and Paypal.

3.What about your steel ball’s quality?

Checking in the whole manufacturing process &100% inspection before shipment ensure the quality of our products.

4.What’s your packing method?

A) Inner packing: Dry packing or oil packing are provided according to you needs.

B) Outer packing:

1)volatile rust preventive paper + poly bag + iron drum + wooden / iron pallet.

2)25kg poly bag + carton + wooden pallet or wooden box.

3)customized packing.

5.What’s your delivery time?

Within 3-30 days according to your required size and quantity.

6.Is your steel ball competitive?

Yes, We are steel ball manufacture more than 30+ years.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Non-Customized |

|---|---|

| Certification: | ISO, IATF16949 |

| Standard Parts: | Yes |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample steel ball

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

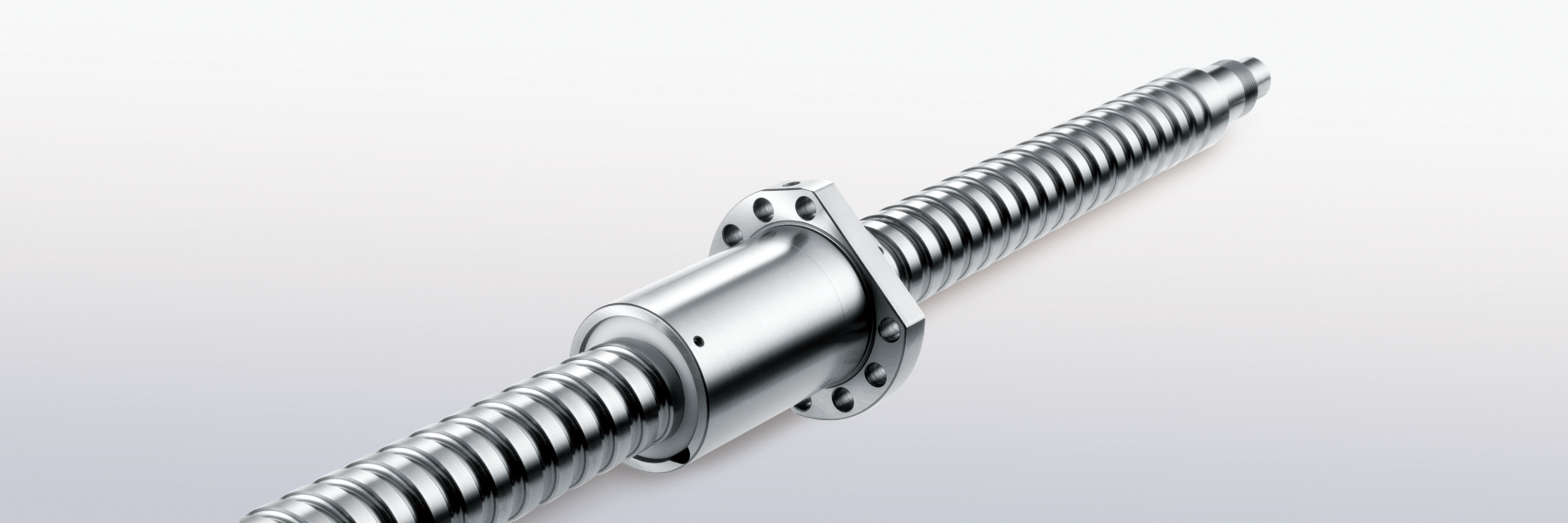

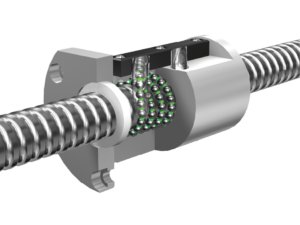

How do screw balls contribute to the efficiency of mechanical systems?

Screw balls, also known as ball screws, play a crucial role in enhancing the efficiency of mechanical systems. They offer several advantages that contribute to improved performance, reduced energy consumption, and increased overall system efficiency. Here are some key ways in which screw balls contribute to the efficiency of mechanical systems:

- High Efficiency of Power Transmission: Screw balls are highly efficient in converting rotary motion into linear motion. The rolling contact between the ball bearings and the screw threads minimizes friction compared to other types of linear motion systems, such as sliding or belt-driven mechanisms. This high efficiency allows mechanical systems to transmit power more effectively, resulting in reduced energy losses and improved overall efficiency.

- Improved Positioning Accuracy and Repeatability: Screw balls provide excellent positioning accuracy and repeatability, making them ideal for applications that require precise linear motion control. The ball bearings’ rolling contact with the screw threads ensures minimal backlash and hysteresis, resulting in accurate and repeatable positioning. This precision eliminates the need for additional corrective actions, reducing inefficiencies and improving the overall accuracy and efficiency of the mechanical system.

- Reduced Friction and Wear: Screw balls are designed to minimize friction and wear between the ball bearings and the screw threads. The rolling contact reduces sliding friction, resulting in less energy loss due to frictional heating. Additionally, advancements in materials and coatings have further reduced friction and wear, extending the screw ball’s lifespan and reducing the need for frequent maintenance and replacement. The reduced friction and wear contribute to improved efficiency and lower operating costs.

- Increased Load-Carrying Capacity: Screw balls are capable of handling high loads due to their ball bearing design. The load is distributed over a large number of ball bearings, allowing for efficient load transmission and reduced stress on individual components. The ability to handle high loads without sacrificing efficiency makes screw balls suitable for applications that require heavy-duty or high-performance linear motion systems.

- Energy-Saving Features: Manufacturers have introduced energy-saving features in screw ball designs to further enhance efficiency. For example, some screw balls incorporate low-friction ball nuts or optimized ball-to-raceway contact, reducing power requirements. Additionally, advancements in lubrication systems and materials minimize energy losses due to friction, resulting in improved energy efficiency and reduced operating costs.

- Integration with Automation and Control Systems: Screw balls can be easily integrated with automation and control systems, allowing for precise and efficient motion control. By integrating screw balls with servo motors, drives, and feedback systems, mechanical systems can achieve accurate and synchronized movement, minimizing errors and inefficiencies. This integration enables advanced automation and control strategies, optimizing system performance and energy usage.

By leveraging the advantages of screw balls, mechanical systems can achieve higher efficiency, improved accuracy, and enhanced performance. The reduced friction, high load-carrying capacity, and energy-saving features of screw balls contribute to lower energy consumption, reduced maintenance requirements, and increased productivity. These benefits make screw balls a popular choice in various industries where efficiency and precision are essential, such as robotics, CNC machines, aerospace, and automotive manufacturing.

How do temperature variations affect the performance of screw balls?

Temperature variations can have a significant impact on the performance of screw balls, also known as ball screws. These linear motion systems are designed to operate within specific temperature ranges to maintain their accuracy, dimensional stability, and overall performance. Here’s how temperature variations can affect the performance of screw balls:

- Thermal Expansion: Screw balls are typically composed of different materials, such as steel or ceramics, that have different coefficients of thermal expansion. When the temperature changes, each material expands or contracts at a different rate, leading to dimensional changes in the screw ball components. This thermal expansion can introduce misalignment, increased backlash, or changes in preload, affecting the accuracy and repeatability of the linear motion system.

- Lubrication: Temperature variations can impact the properties and performance of the lubricant used in screw balls. Lubricants have specific viscosity and temperature ranges in which they function optimally. High temperatures can cause lubricants to thin out, reducing their ability to provide sufficient lubrication and increasing friction between the ball bearings and the raceway. On the other hand, low temperatures can cause lubricants to thicken, impeding smooth motion and increasing resistance. Insufficient or improper lubrication due to temperature variations can lead to increased wear, reduced efficiency, and potential premature failure of the screw ball system.

- Material Integrity: Extreme temperature variations can affect the mechanical properties and integrity of the materials used in screw balls. High temperatures can cause thermal degradation, softening, or even melting of certain materials, leading to reduced strength, increased wear, and potential deformation. Conversely, low temperatures can make materials brittle and more susceptible to fracture or failure under load. It is important to consider the temperature limits of the screw ball materials to ensure their structural integrity and long-term performance.

- System Rigidity: Temperature changes can affect the rigidity and stiffness of the screw ball assembly. When subjected to high temperatures, the components may expand, leading to a decrease in overall system rigidity. This reduction in stiffness can result in increased deflection, reduced accuracy, and diminished load-carrying capacity. Conversely, low temperatures can cause contraction and increased system rigidity, potentially affecting the smoothness of motion and overall performance.

- Sealing and Environmental Protection: Temperature variations can impact the effectiveness of seals and environmental protection measures in screw ball assemblies. Seals play a crucial role in preventing contaminants, moisture, and debris from entering the system. Extreme temperature changes can cause seals to degrade, lose flexibility, or become brittle, compromising their sealing properties. This can result in increased risk of contamination, accelerated wear, and reduced performance of the screw ball assembly.

To mitigate the effects of temperature variations on screw ball performance, several measures can be taken. These include:

- Choosing materials with suitable temperature resistance and low coefficients of thermal expansion.

- Using lubricants that are specifically formulated for the expected temperature range.

- Implementing temperature compensation techniques to maintain dimensional accuracy and alignment.

- Applying thermal barriers or insulation to minimize the transfer of heat to the screw ball assembly.

- Ensuring proper sealing and protection from extreme temperature environments.

- Using temperature control systems or environmental enclosures to maintain a stable operating temperature.

By considering the potential effects of temperature variations and implementing appropriate measures, the performance and longevity of screw balls can be optimized, ensuring accurate and reliable linear motion in various applications.

How do you select the right size of a screw ball for a specific application?

Selecting the right size of a screw ball, or screw, for a specific application involves considering several factors that influence the functionality and performance of the screw. Here are some key considerations when determining the appropriate size:

- Thread Type: The first step in selecting the right screw size is to determine the thread type required for the application. Common thread types include machine screw threads, wood screw threads, self-tapping screw threads, and sheet metal screw threads. Each thread type has specific dimensions and characteristics that influence the choice of screw size.

- Diameter: The diameter of the screw is a critical factor in determining its size. It is typically measured as the major diameter, which is the outside diameter of the threaded portion of the screw. The diameter should match the size of the hole or the material being fastened. Using a screw with the correct diameter ensures proper thread engagement and adequate holding strength.

- Length: The length of the screw is determined by the thickness of the materials being joined. The screw should be long enough to penetrate through the first material and provide sufficient engagement in the second material to create a secure connection. It is important to consider the total thickness of the materials and any additional components, such as washers or spacers, when determining the appropriate screw length.

- Head Type: The head type of the screw should also be considered for specific applications. Common head types include flat head, pan head, round head, and countersunk head. The choice of head type depends on aesthetic preferences, flushness requirements, and the type of tool used for installation.

- Material: The material of the screw should be selected based on the application’s environmental conditions and the materials being fastened. Different materials offer varying levels of corrosion resistance, strength, and compatibility with specific materials. Common screw materials include stainless steel, carbon steel, brass, and aluminum.

- Load and Application: Consider the anticipated load and the specific application requirements. If the screw will be subjected to heavy loads or vibrations, it may be necessary to choose a larger size or a screw with additional features like locking threads or increased tensile strength.

When selecting the right size of a screw ball, it is essential to consult the manufacturer’s specifications, guidelines, or engineering resources specific to the application. These resources often provide detailed information on recommended screw sizes based on the intended use, material compatibility, and load requirements.

It is also advisable to consult with professionals, such as engineers or experienced tradespeople, who have expertise in the specific application or industry. They can provide valuable insights and recommendations based on their experience and knowledge of best practices.

By considering factors such as thread type, diameter, length, head type, material, load, and application requirements, the appropriate size of a screw ball can be selected to ensure optimal performance, durability, and reliability in a specific application.

editor by CX 2024-03-09

Leave a Reply